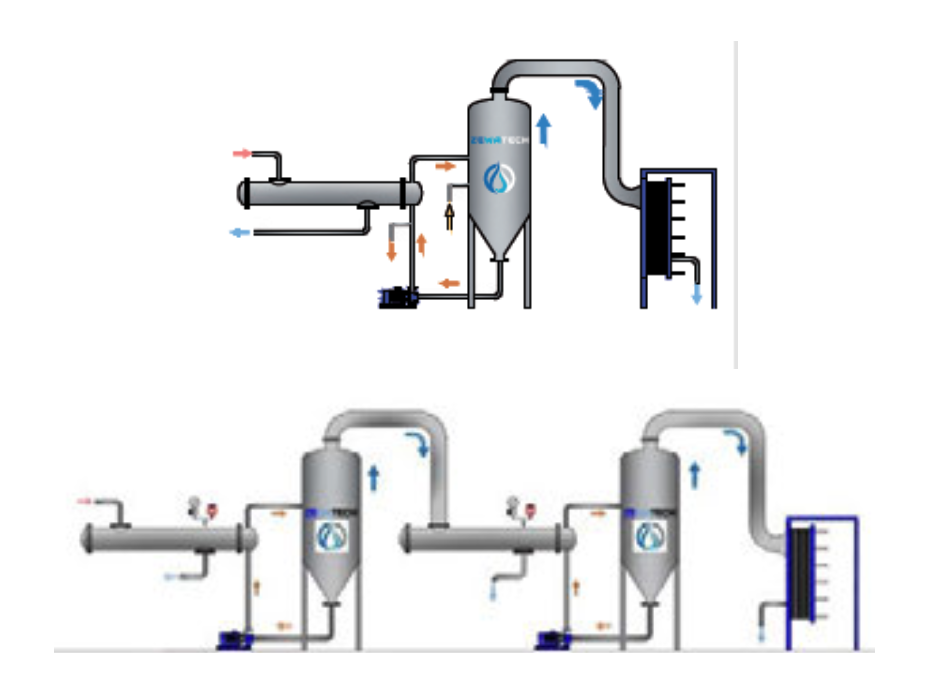

Vacuum Evaporator

Versatile Thermal Transfer Evaporators (VTS)

Efficiency and Versatility with Diversified Energy Sources

The evaporators of(VTS) Versatile Thermal Sourcesfrom ZEWATECH represent an efficient and adaptable solution for wastewater treatment, taking advantage of various excess energy sources available in many industries such as steam, thermal oil or hot water.

Main Features:

Optimal Energy Utilization

They utilize excess steam, hot water, or cogeneration cooling, providing efficient energy management. Depending on the number of effects, consumption can reach 190,000 Kcalh/m3 (4 effects) and 576,000 Kcalh/m3 (1 effect).

Thermal Utilization from 45º

Ability to utilize heat from 40º, maximizing process efficiency.

Electrical Consumption (apart from thermal)

Only electricity is required for the pumps, with a consumption of 12-30 kW/m³.

Capacity for Various Volumes

Suitable for treating volumes of 5 to 100 m³/day or 100l to 500K liters per day.

Water Reuse and Concentrate Recovery

They facilitate the reuse of water and the recovery of concentrated products.

Low Boiling Temperature and Evaporation Conditions

They operate in a boiling temperature range of 30 – 35°C and at pressures of 4 – 30 kPa.

Effects and Energy Consumption:

Single Effect:Consumption of (576,000 Kcal.h/m3 – 600 kW·h/m³)

Multi-effects: They allow reduced energy consumption.

Innovative Operation

The VTS operate with a central boiler that evaporates from 30 degrees of temperature thanks to a powerful vacuum system. Heat is usually transmitted through removable tubular exchangers, facilitating their maintenance and cleaning. The steam condensation is carried out through flat exchangers fed with tower waters or adiabatic coolers, generating high quality distilled water.