Industrial Evaporators

Mechanical Vapor Compression (MVC) Evaporators

Energy Efficiency and High Performance

TheMVC evaporators from ZEWATECHstand out in the market for their high efficiency and low energy cost. Thanks to the use of a steam compressor, these systemsincrease latent heat through the volumetric compression of the steam generated in the boiling boiler, resulting in an energy-efficient and cost-effective processsince there is only the electric consumption generated by the steam compressor.

Main features of MVC industrial evaporators:

Power Supply Only

With an energy consumption between 14 and 70 kW/m³, these evaporators are an optimal solution for wastewater treatment, combining efficiency and sustainability.

Large Volume Capacity

Ideal for large applications, with capacities ranging from 1 m3/day to 100 m³/day.

Water Reuse

These systems facilitate water reuse, aligning with sustainability and resource conservation policies.

Valorization of Concentrated Products

They allow the recovery and valorization of by-products, contributing to the circular economy.

Boiling Temperature Range

They operate in a range of 65 – 90 ºC, optimizing the evaporation process

Condiciones de Evaporación Óptimas

Funcionan a presiones de 7-9 kPa, garantizando una evaporación eficiente.

Technological Morphologies

(based on waste type and concentration)

Types of circulation

Forced

Natural (Thermosiphon)

Falling Film

Other morphologies

Recovery of volatiles

Stripping

Crystallization

OperationInnovative

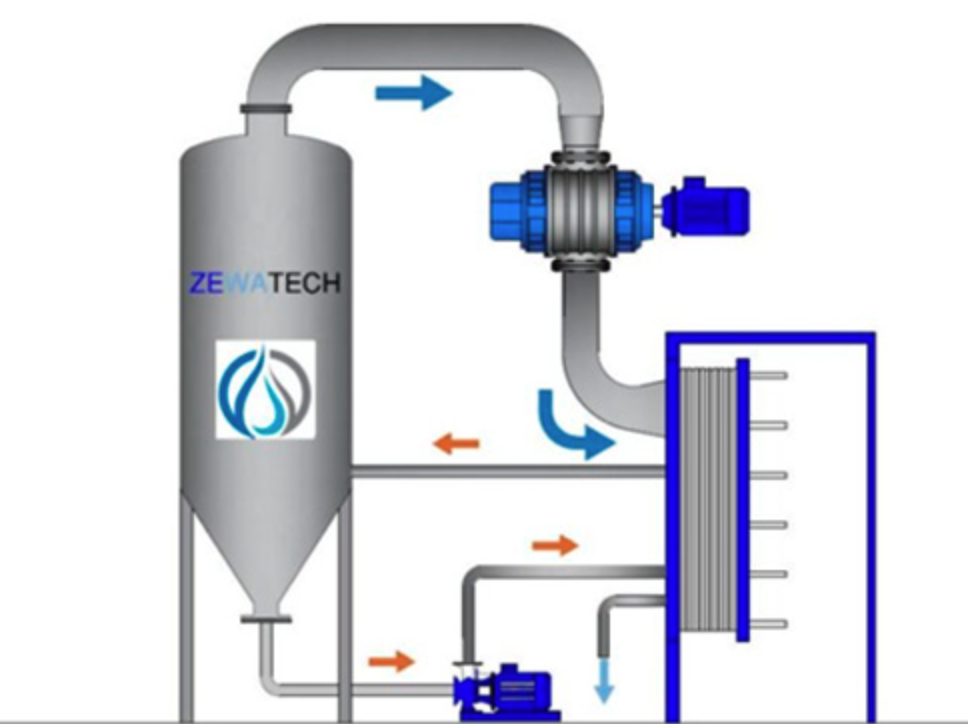

In MVC evaporators, the vapors generated at 70ºC in the boiler are compressed, raising their temperature up to 130°C. This compression process increases the thermal enthalpy. The compressed vapors heat the boiler water through a heat exchanger, where they also condense, producing high purity distilled water.

Continuous Innovation and the TurboFlash System

Recently, we have further optimized the mechanical steam compression system, incorporating unique technological innovations in Europe. Thanks to this R&D effort, we have managed to further reduce energy costs to 15-30 kW/m³, which sets us apart in technical solvency and energy efficiency.

The TurboFlash system is our latest innovation, a combination of mechanical steam compression with specially treated steam turbines to handle gases and volatiles. These turbines, made with special high-speed alloys, together with the Flash water spraying system in the boiler, allow for more efficient evaporation and a state change of the water that significantly reduces energy costs.

SUCCESS CASE:

Implementation of the TURBOFLASH System at the SELECCIÓ DESEURAS SL Biogas Plant

Recently,ZEWATECHcarried out a notable project at the biogas plant ofDESEURAS, where they faced a significant challenge with the treatment of digestate. After going through centrifugation processes, physico-chemical treatment and ultrafiltration, the resulting concentrate still contained high levels of ammonia and other substances that made it unsuitable for discharge into the environment.

DESEURAScontactedZEWATECHseeking an efficient solution to this problem. Initially, several proposals were evaluated, but they were discarded due to the high ammonia content in the water. This is where theTURBOFLASHtechnology showed its true potential.

Thanks to theTURBOFLASHsystem, ammonia was no longer an obstacle. This technology allows separating ammonia in the form of ammoniacal gas, turning a problem into a significant advantage. The stripping process of the ammonia contained in the liquid fraction of the digestate is carried out efficiently, allowing its removal and improving the quality of the treated effluent.

To validate the proposed solution,ZEWATECHconducted a pilot test for three weeks at the facilities ofDESEURASwith a pilot plant. The results were thoroughly analyzed, and the feasibility of the project was tangibly demonstrated. With these results in hand, the client accepted the technological challenge of theTURBOFLASH.

Since its implementation, theTURBOFLASHsystem has exceeded all expectations at the biogas plant ofDESEURAS. The results have been exceptional both in terms of energy cost and operational performance. An efficient separation and removal of ammonia has been achieved, far exceeding the project’s objectives.

This success has marked a turning point in the treatment of digestates, not only at the plant ofDESEURAS, but in the general management of these liquid fractions. Now, the treated wastewater can be reused for irrigation or discharged directly into the environment, with concentrates that can be valued as by-products, including ammonia.

TheTURBOFLASHsystem fromZEWATECHrepresents a significant advance in the treatment of industrial wastewater, offering greater efficiency, lower maintenance costs and superior versatility in its applications. If your company faces challenges with wastewater treatment and is looking for advanced and efficient solutions, theTURBOFLASHmay be the answer.

MVC Pilot Plant

Zewatech has several pilot plants using MVC evaporation technology, designed to perform customized tests with customer wastewater. This flexibility allows not only testing at Zewatech facilities, but also bringing the pilot plants directly to the customer’s facilities, ensuring a tailored and optimized solution for their specific water treatment needs.